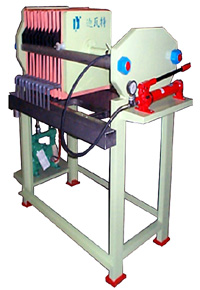

In the plate filter press, dewatering is accomplished by forcing the water from the sludge under high pressure.

The sludge is pumped into the filter press chambers and the filtrate is pressed through the filter clothes as pumping pressure increases.

The dewatered sludge is retained inside the press chambers and moved as the sludge cake after a press run.

and dewatered by squeezing of the rolls.Please see more information on our website

Tel:886-2-29334329

fax:886-2-2399-8100

e-mail:dewater@ms9.hinet.net

web:http://www.hidewater.com

The sludge is pumped into the filter press chambers and the filtrate is pressed through the filter clothes as pumping pressure increases.

The dewatered sludge is retained inside the press chambers and moved as the sludge cake after a press run.

and dewatered by squeezing of the rolls.Please see more information on our website

Tel:886-2-29334329

fax:886-2-2399-8100

e-mail:dewater@ms9.hinet.net

web:http://www.hidewater.com

Specifications

- Purpose:

- Liquid/ Solid separation through pressure filtration.

- Applications:

- 1. Stone/Clay/Ceramic Processing Industry.

- 2. PC Board Industry/Electroplating Industry.

- 3. Solvents and Process Solution Clarification.

- 4. Reduction of Metal Finishing Waste.

- 5. Oil Field Slurry.

- 6. Chemical Product Processing.

- 7. Food and Beverage Processing.

- 8. Metal Finishing Waste.

- 9. Tanning/Leather Processing.

- Charaacteristics:

- 1. Pressurize the filter plate by manual hydraulic pump (Maximum: 10,000 psi).

- 2. Manual operation to open each filter plate chamber.

- 3. Durable rubber filter plates for light, medium, and high tension operations.

- 4. Simple structure and easy maintenance.

- 5. No electric power needed.

- 6. Cost-effective operation.

Features

- Mobile and integrated modular design.

- No chemical additives/ polymer needed.

- The pressed sludge cake is collected by conveyors and transported to the dedicated location/ storage bins.

- Applicable to various sludge an dprocessing applications.

| Model | Chamber Filter Area (m^2) | Filter Area (m^2) | Filter Vol. (L) | Power | Dimentions (mm) |

|---|---|---|---|---|---|

| HD50-10 | 10 | 4.7 | 63.4 | Manual Hydraulic Pump | 1300x760x1000 |

| HD50-15 | 15 | 7.0 | 95.2 | Manual Hydraulic Pump | 1600x760x1000 |

| HD50-20 | 20 | 9.4 | 126.9 | Manual Hydraulic Pump | 1900x760x1000 |

| HD50-25 | 25 | 11.7 | 158.7 | Manual Hydraulic Pump | 2200x760x1000 |

| HD50-30 | 30 | 14.0 | 190.4 | Manual Hydraulic Pump | 2500x760x1000 |

| HD50-35 | 35 | 16.5 | 221.9 | Manual Hydraulic Pump | 2800x760x1000 |

| HD50-40 | 40 | 18.8 | 253.8 | Manual Hydraulic Pump | 3100x760x1000 |

| HD50-45 | 45 | 21.2 | 285.5 | Manual Hydraulic Pump | 3400x760x1000 |

| HD50-50 | 50 | 23.5 | 317.2 | Manual Hydraulic Pump | 3700x760x1000 |

| HD50-55 | 55 | 25.9 | 348.7 | Manual Hydraulic Pump | 4000x760x1000 |

| HD50-60 | 60 | 28.2 | 380.6 | Manual Hydraulic Pump | 4300x760x1000 |

| HD50-65 | 65 | 30.6 | 412.3 | Manual Hydraulic Pump | 4600x760x1000 |

| HD50-70 | 70 | 32.9 | 443.8 | Manual Hydraulic Pump | 4900x760x1000 |

Main Products

environment equipment ,Filter Press, Dosing System, DAF system, Sand Filter, Auto Bar Screen,Dewater products