| Materials | Grade | Br (Gs) | iHc (Oe) | bHc (Oe) | Bh max. (MGOe) | Density G/cm^3 | TC Celsius | aBr % Celsius |

|---|---|---|---|---|---|---|---|---|

| Sintered alnico 2 | Flng12 | 7000 | 540 | 500 | 1.5 | 7 | 810 | -0.014 |

| Sintered alnico 3 | Flng8 | 5200 | 540 | 500 | 1 | 6.7 | 760 | -0.022 |

| Sintered alnico 4 | Flng14 | 5000 | 770 | 750 | 1.8 | 7 | 850 | -0.02 |

| Sintered alnico 5 | Flng28 | 10500 | 590 | 580 | 3.5 | 7 | 890 | -0.016 |

| Sintered alnico 5 | Flng34 | 11200 | 603 | 591 | 4.27 | 7 | 890 | -0.016 |

| Sintered alnico 6 | Flng25 | 9000 | 730 | 700 | 3.3 | 7 | 850 | -0.02 |

| Sintered alnico 7 | Flng18 | 6500 | 1030 | 1000 | 2.3 | 7 | 850 | -0.02 |

| Sintered alnico 8 | Flngt31 | 7800 | 1280 | 1250 | 3.5 | 7 | 850 | -0.02 |

| Sintered alnico 9 | Flngt36 | 6800 | 1738 | 1700 | 4.6 | 7 | 850 | -0.011 |

| Sintered alnico 9h | Flngt38 | 8000 | 1525 | 1500 | 4.75 | 7 | 850 | -0.011 |

| Cast alnico 2 | Lng10 | 6000 | 540 | 500 | 1.2 | 6.9 | 760 | -0.022 |

| Cast alnico 3 | Lng13 | 6600 | 610 | 600 | 1.6 | 7.3 | 810 | -0.014 |

| Cast alnico 5 | Lng37 | 12000 | 610 | 600 | 4.63 | 7.3 | 890 | -0.016 |

| N/A | Lng40 | 12500 | 610 | 600 | 5 | 7.3 | 890 | -0.016 |

| N/A | Lng44 | 12500 | 660 | 650 | 5.9 | 7.3 | 890 | -0.016 |

| N/A | Lng52 | 13000 | 710 | 700 | 6.5 | 7.3 | 890 | -0.016 |

| Cast alnico 6 | Lng30 | 10500 | 750 | 740 | 3.5 | 7.3 | 890 | -0.016 |

| Cast alnico 8 | Lngt32 | 8000 | 1250 | 1250 | 4 | 7.3 | 950 | -0.02 |

| N/A | Lngt38 | 8000 | 1400 | 1380 | 4.75 | 7.3 | 950 | -0.02 |

| N/A | Lngt60 | 9000 | 1400 | 1380 | 7.5 | 7.3 | 850 | -0.035 |

| N/A | Lngt72 | 10500 | 1400 | 1400 | 9.1 | 7.3 | 850 | -0.025 |

| Cast alnico 9 | Lngt44 | 9000 | N/A | 1550 | 5.5 | 7.3 | 850 | -0.025 |

| N/A | Lngt63 | 9000 | N/A | 2000 | 8 | 7.3 | 850 | -0.025 |

Features

- Wide range of internationally compatible alloys

- High field strengths at medium prices

- Excellent temperature characteristics with a reversible coefficient of induction of -.02% per degree C

- Highest operating temperature range of any permanent magnet material

- Compatible with most painting or plating systems (including nickel and copper)

- Wide range of complex shapes and sizes available

- Ease of calibrating magnets or assemblies for precise levels of performance

- Mature product technology

- Lower initial tooling cost when compared with most other permanent magnet materials

- Can be silver soldered to other circuit components

- Low field strengths required for saturation makes magnetizing after assembly practical

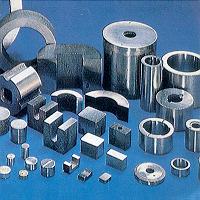

Main Products

magnet