For accurate trap selection, refer to our condensate capacity graph. Open the inlet valve to the trap gradually, allowing condensate to fill the body of the trap initially. In case the prime is lost, repeat the above procedure. For this reason, by pass lines should be above the trap, to avoid loss of prime, when operated.

| Model | Size (in) | Size (mm) | A | B | C | D |

|---|---|---|---|---|---|---|

| HB-15L | 1/2 | 15 | 130 | 180 | 230 | 163 |

| HB-20L | 3/4 | 20 | 144 | 202 | 230 | 163 |

| HB-15 | 1/2 | 15 | 178 | 223 | 290 | 211 |

| HB-20 | 3/4 | 20 | 193 | 273 | 290 | 260 |

| HB-25 | 1 | 25 | 218 | 309 | 310 | 291 |

| HB-40 | 1(1/2) | 40 | 250 | 344 | 420 | 312 |

| HB-50 | 2 | 50 | 280 | 370 | 420 | 328 |

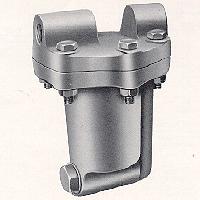

Specifications

- End connection: Screwed / Socket Weld / Flanged.

- Maximum Operating

- Model HB-15L & HB-20L: 25kg/cm^2

- Model HB-15 & HB-50: 40kg/cm^2

- Maximum Operating Temperature: 426 Celsius

Features

- IBR approved

- Horizontal configuration - side inlet/outlet (inline)

- Cast steel body, all stainless steel internals

- Hardened valve and seat of chromium steel

- Automatic are venting, no start-up sluggishness

- Ideal for condensate return systems with upto 90% back pressure

- Integral strainer reduces malfunctioning and damage due to dirt particles

- High condensate handling capacity even at low pressures

- Material:

- Body: C.S. as per ASTM A216 Gr. WCB

- Cover: C.S. as per ASTM A216 Gr. WCB

- Bucket: AISI 304

- Bucket Weight: Carbon Steel

- Valve & Seat: Chromium Steel (Hardened)

- Linkages: AISI 304

- Strainer Screen: AISI 304 Perforated Sheet

Main Products

thermodynamic steam traps, inverted bucket steam